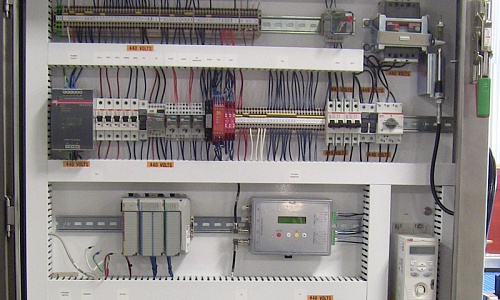

The system software provides complete monitoring of the tempering process and allows safe and easy operation of the equipment by any of your operators. The complete system is powered using up to four of the AMT7510 microwave transmitter assemblies.

Some of the advantages of using AMTek’s microwave tempering equipment include:

The newest and most sophisticated microwave tempering oven available in the world today

AB modem assembly included for software updates and access to the entire systems operation

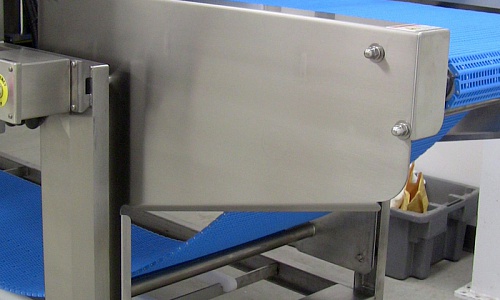

Entire system constructed from stainless steel materials

Higher quality food products to your customers

Reduction in raw materials levels by substantially reduced tempering times

Reduction in raw material handling requirements

Adds flexibility to processing by allowing tempering on demand

CE option for Europe

AMTek takes your installation requirements and provides complete facility layouts, detailing oven location, utility requirements and location, making the installation a part of our commitment to your specific needs. We also offer as options to your equipment complete support hardware including:

-

Mezzanine assemblies designed, manufactured and certified by a structural engineer

-

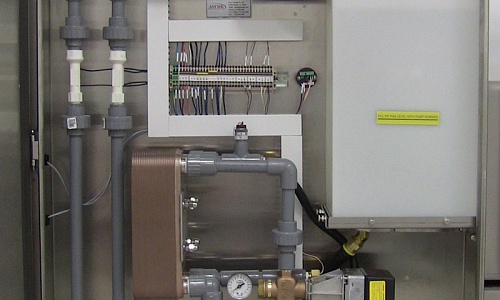

Carrier industrial chillers systems for closed loop glycol cooling requirements

-

Belt Washer Systems

-

High velocity blower assemblies

-

Spare parts assemblies

- Available in two standard length ovens of 8.5 and 9.7 Meters overall.

-

Custom oven lengths are also available.

-

Continuous flow tempering oven assembly.

-

Designed for high volume processing requirements.

-

Standard tempering oven common worldwide.

-

Tempering of most any frozen products.

-

Modular in design for easy capacity upgrades.

- Process rates of up to 8 metric tons per hour.